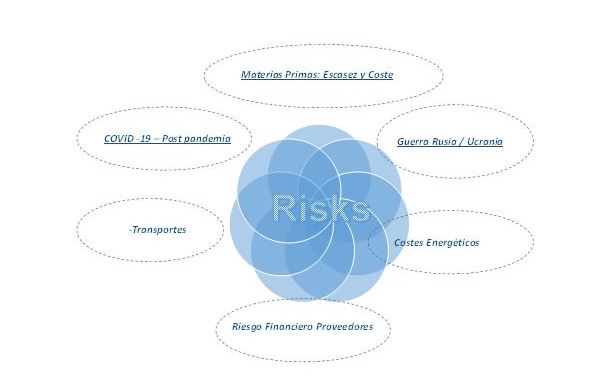

For more than two years now, the impact of external factors that began with the outbreak of COVID 19 worldwide and its consequences on global trade have led to a convulsive situation, with shortages of raw materials, rising fuel prices and energy costs, block in the transport of goods, all recently aggravated by the war in Ukraine and the economic sanctions imposed on Russia, which has led to a excessive increase in the prices of raw materials, disruption of logistics routes, and tension in the supply chain.

But these are not the only factors affecting trade. Another essential element is the recent lockdown in China to prevent the spread of Covid-19, which “are again disrupting maritime trade at a time when supply chain pressures seemed to be easing.

What have we learned?

We have many lessons learned, the disruption and impact on the Supply Chain is forcing us to operate under unknown exceptionalities. Solid and agreed protocols will be necessary to understand what the opportunities are in a global market that will seek to reposition itself and in some cases even reinvent itself in search of the “New Normality”; the definition of contingency plans to ensure continuity in disruptive scenarios; the establishment of clear communication strategies in crisis situations and collaboration with our suppliers and customers in order to buid strategic alliances to achieve flexibility and resilience. We must not overlook the importance of SMBs, local products, which have successfully supplied globalization in difficult times, and see how we can include them in these schemes.

Main challenges

The aerospace market foresees an emerging post-pandemic scenario sustained in the coming years and, on the other hand, the integration of Hamble and Évora in the Aernnova Group, the transversality and synergies between companies, place the Procurement Department in front of new and important challenges to face:

Focus on the customer (internal and external). Generate value proposition.

Focus on the processes. Improve processes to support the value proposition. Agile and Lean methodologies.

Development of inter-company collaboration. Develop trust as a basis for strategic alliances, integrated platforms, and jointly seek new business models, product development and innovation.

Risk management. Permanent monitoring of critical points in the logistics chain is needed and contingency plans must be designed to react quickly to disruptions. Technology and timely information must become strategic factors.

Cost improvement plans without losing product/service value to improve global competitiveness.

Digital commitment. Technology must be implemented for the flow and analysis of information.

After analyzing the situation of the supply chain and knowing the main future challenges, the Procurement / Supply Chain Management is facing a reorganization in order to have a single, global and integrated management of direct and indirect Procurement, centralized in strategy and local know-how, and with close operational ways. It is based on three unquestionable and basic pillars to guarantee a good performance: (i)guarantee the supply of both parts and services within the established deadline, avoiding delays that generate distortions, (ii) comply with the required quality standards and of course, (iii) constantly searching for efficiency and economic improvement that makes us always competitive.

In conclusion, if an organization wants to continue to grow and evolve into the future, one of the keys lies in its supply chain.

The supply chain must be fully integrated with new technologies in order to be competitive and the actors involved throughout the process must be qualified and have the capacity to adapt quickly to all changes.