Within the framework of the FEINDEF 2025 Exhibition, a demonstrator was presented by Aernnova Engineering Division and the ITA – Aragon (Spain) Institute of Technology, showcasing a Structural Health Monitoring (SHM) system installed on a curved panel made of carbon fiber reinforced polymer (CFRP), reinforced on the opposite side with stiffeners. This system is based on a network of piezoelectric sensors (PWAS), optimally distributed over the surface of the panel (on the rear side), capable of detecting impacts through the elastic waves (Lamb waves) generated by them.

The following images show aspects of the sensor installation and the connection of the channels to avionics that have yet to be miniaturized.

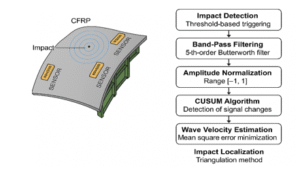

When an impact occurs on the structure, acoustic waves are generated and propagate through the material. In thin plates or sheets made of isotropic materials such as aluminum, these waves are known as Lamb waves and travel circularly and uniformly. In curved composite materials such as CFRP, the wave behavior is more complex, yet still detectable. The piezoelectric sensors convert these mechanical vibrations into electrical signals. If the signal from any of the sensors exceeds a predefined threshold, the system is activated and all sensors simultaneously record the event. The underlying engineering process follows this scheme:

To analyze the signals, they are first filtered using a Butterworth algorithm, which removes noise and frequencies that do not provide useful information.

Next, the signals are normalized to the same scale, allowing accurate identification of the moment each sensor receives the wave (Time of Arrival or ToA). This moment is detected using an algorithm called CUSUM, which analyzes small changes in the signal to find a turning point—i.e., the exact moment when the wave starts.

The final impact location is calculated using a geometric method inspired by a classical problem from antiquity: Apollonius’ problem. This involves finding a circle tangent to three others. In this case, the three circles are constructed from the positions of three sensors and the differences in their arrival times. The center of the resulting circle indicates the point of impact, and its radius shows the distance to the nearest sensor. To determine the impact location, it is not necessary to know the exact wave propagation speed. An estimated speed is used initially, and after the first localization, it is refined by comparing measured times with the distances between sensors.

The following image presents a diagram of the overall system operation:

Once the impact points are obtained, they are sent to a monitor that displays the panel and the location of the damage:

This functionality can be used, for example, on aircraft lower panels, as shown in the following image, in order to detect low- and medium-speed impacts such as those caused by FOD (Foreign Object Debris).

The advantages of integrating instrumented panels with damage detection capability into aircraft include:

-Thinner panels result in a significant reduction in structural weight, leading to:

Lower fuel consumption, resulting in cost savings and reduced pollutant emissions.

Greater operational efficiency, which is highly valued by aircraft manufacturers (OEMs such as Airbus, Boeing, Embraer…).

-By offering lighter structures without compromising safety, Aernnova can present a differentiated value proposition compared to the competition.

-The incorporation of impact detection systems (such as piezoelectric sensors) allows for:

Continuous structural monitoring (SHM – Structural Health Monitoring).

Early detection of invisible impact damage (such as those caused by tools, hail, or birds), reducing the risk of catastrophic failures.

These technologies improve operational safety and allow for optimized maintenance cycles.

Thanks to real-time impact detection, operators can:

Avoid frequent manual inspections (which require grounding aircraft).

Plan corrective maintenance only when necessary, instead of following fixed schedules.

This translates to cost reductions for airlines, making suppliers like Aernnova more attractive to manufacturers.

-The combination of structural lightness and advanced monitoring represents a high-value technology, aligned with the demands of:

Future commercial aviation (for sustainability and efficiency).

Military programs (for robustness and structural monitoring).

By mastering this capability, Aernnova can position itself as a strategic supplier, increasing its chances of participating in high-tech programs.

-Aeronautical authorities and manufacturers are promoting the use of SHM technologies to improve traceability, safety, and sustainability.

-By integrating such systems into thin structures, Aernnova demonstrates its innovation capability, making it more attractive for new contracts and technological alliances.

Aernnova’s ability to manufacture thin panels with impact detection systems allows it to offer lighter, safer, smarter, and more competitive products. This results in a stronger market position compared to other suppliers who have not yet achieved this level of technological integration. It reinforces its role in the global aerospace value chain.