In Aernnova we are aware of the environmental impact of the industrial activities we develop, and therefore, we work on the reduction of these impacts through the implementation of the Best Available Technologies (BAT) in the market.

An outstanding example of this spirit of continuous improvement can be found in BURULAN.

BURULAN moved its machining activity with oil lubricant to the Miñano facilities in 2018, and since then and progressively, actions have been carried out with clear improvements from an environmental point of view.

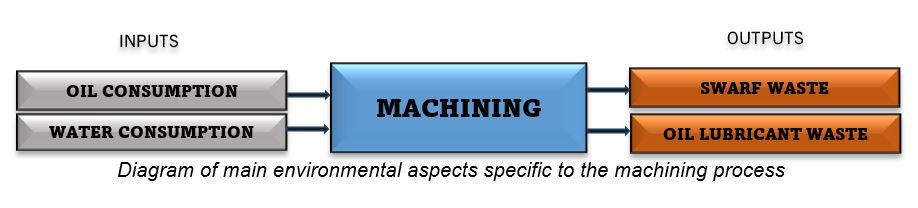

The use of oil lubricant has an environmental impact not only due to the use of the raw material oil, but also due to water consumption, the generation of metal swarf waste and oil lubricant waste, once its lifetime is over.

Progressively, improvements have been implemented such as the installation of a centralized chip and cutting oils system, cutting oils supply with “conscious” activation guns, filtering of oil lubricants and oils, installation of briquetting machines and the use of returnable containers with waste subcontractor. All these actions reduce the environmental impact and have achieved the following environmental improvements:

1.- To reduce the consumption of oil and water. In Miñano, 10% of the water consumption is due to the preparation of the machining oil lubricant.

2.- To reduce the generation of oil lubricant waste.

3.- Reduce the number of trips required to move the metal swarf, now in the form of briquettes.

4.- Improve waste management through recycling and not landfilling.

5.- Reduce the emission of pollutants into the atmosphere.

In addition, all these actions contribute to the reduction of CO2 emissions associated with this process and therefore, to the mitigation of the effects of climate change in line with the company’s 2030 Sustainability strategy and objectives.

However, we are ambitious and the improvement is unlimited, and other improvements to be implemented have already been identified, the most important of which is the increased automation of the collection of swarf and oil lubricant in the centralized system in those machines that are currently not directly connected.

.