Continuous Improvement in the elimination of everything that does not add value is one of our management commitments and values, as it is explicitly stated in our Code of Ethics, as well as in the pillars that support Aernnova’s Strategic Plan. Therefore, it is advisable to review what has been done and, specially, the next steps on this roadmap towards EXCELLENCE which began in 2009.

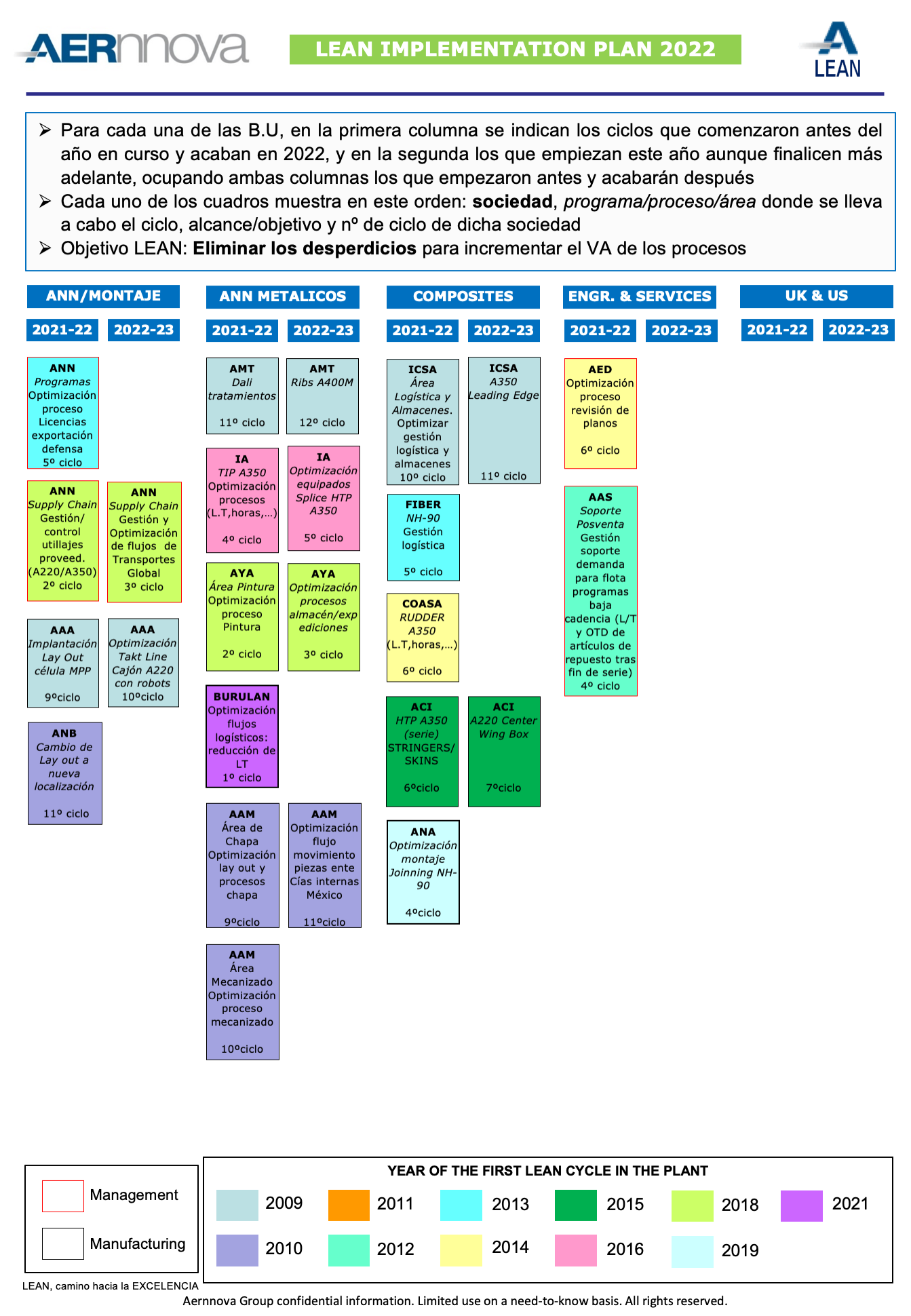

All Aernnova companies, to a greater or lesser extent, depending on the year in which they started, have integrated the corporate LEAN deployment model into their management plans, consisting of continuous improvement cycles that, year after year, examine and optimize the value processes.

Those companies that started first (Aernnova Aeroestructuras Álava, Internacional de Composites, Aerometallic Tarazona, Aernnova do Brasil and Aernnova México) will carry out their 10th, 11th or 12th LEAN cycles this year, and this undoubtedly means the achievement of greater maturity in the optimization of their processes and in the cultural transformation of their organizations, which has visibly contributed to high performance and customer satisfaction indicators.

There is a LEAN 2022 Implementation Plan showing the cycles that will be carried out during this year in each of the companies.

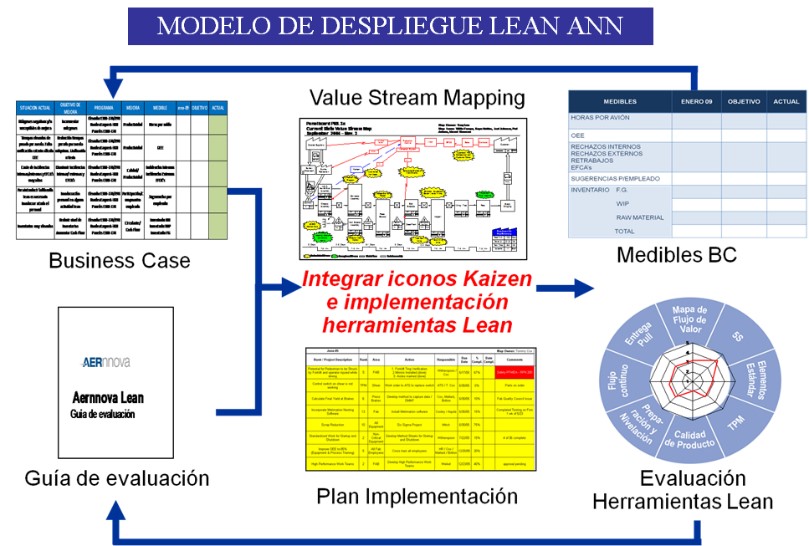

With the main LEAN tool, Value Stream Mapping (VSM), we are able to map and analyze the current state of our information, material and process flows, identifying which elements are not adding value, and establishing a plan to eliminate them.

The priority of these improvement actions must be linked to the Company’s Strategic and Operational Plans. In addition, the connection of the LEAN Culture and Implementation Plans with the corporate and social values of sustainability is evident:

Achieving better energy efficiency, reducing waste and optimizing the consumption of natural resources is a priority and an ethical responsibility for all of us that must gradually reach all the people and processes of the organization.

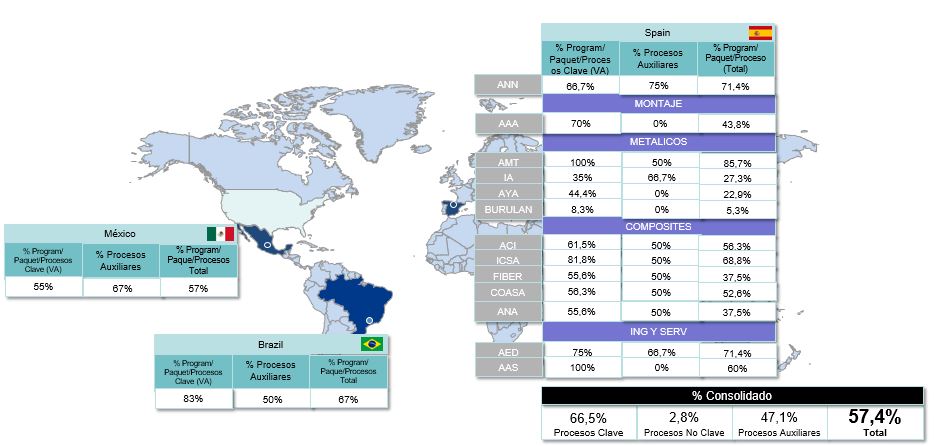

Below you will see a world map showing the percentage of processes in each of the companies where LEAN Cycles (and therefore VSM) have been carried out. The reference base is provided by the process map established in the Corporate Process Manual (MDG-00-005), prioritizing the Key programs/packages/processes against the Non-Key ones (due to their greater or lesser contribution to the generation of value), and also including the Auxiliary processes, which without constituting value-added processes themselves are necessary for the operation of these others, for example, the commercial management (understood as commercial management in its wider role established in a contractual & commercial framework) or financial management processes.

It also shows the evolution of cultural change, which we measure through audits, which evaluate the maturity in the use of the 8 LEAN tools that appear in our Deployment Model. This indicator is used to measure the evolution of our Cultural Change as an organization and to establish medium and long term strategic objectives.