Many times I wonder what “Design to Cost” is, what is intended with Design to Cost, what can I contribute as Design to Cost. There are many teams involved in this task. Basically, each and every one of the work packages that are in the production phase, there are teams whose mission is to propose and analyze ideas that lead to reductions in production costs, seeking greater efficiencies, process improvements, modification of configurations and solutions that are more beneficial for the program, being equally valid technically.

But, what else are we been requested? Are we satisfied with just proposing a cheaper screw, a simpler paint scheme, a more easily achievable product structure? Yes to all?

-Look for radical ideas, Javier, “quantum leaps” that cause important changes in the Product and in the Process…

There are many messages and “strong ideas” that come to me:

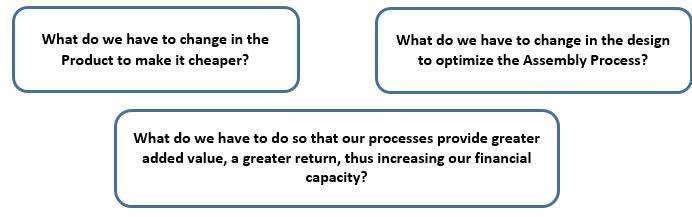

In the following figure we can see a summary what we are looking for with our task:

When you visit the ANN Plants, you have the opportunity to see in detail the steps that are followed in the different manufacturing processes and you add them to the “Shopping List” of the shortcomings and difficulties that day to day entails. Lots of Opportunities. You realize that things, in principle simple, have to be solved through the “tricks” and expertise of the most expert operators.

Many people tell you the most important “technical” problems with the idea that you have a “magic wand” that allows you to find the solution to everything by changing a drawing here, putting a note there…; but this is not a matter of magic. Many of the programs are “Build to Print” and therefore we do not have the “ownership” of the design or the calculation, this makes it very difficult to make the changes come to fruition.

And then what can we do, what can we contribute to what is already being done?

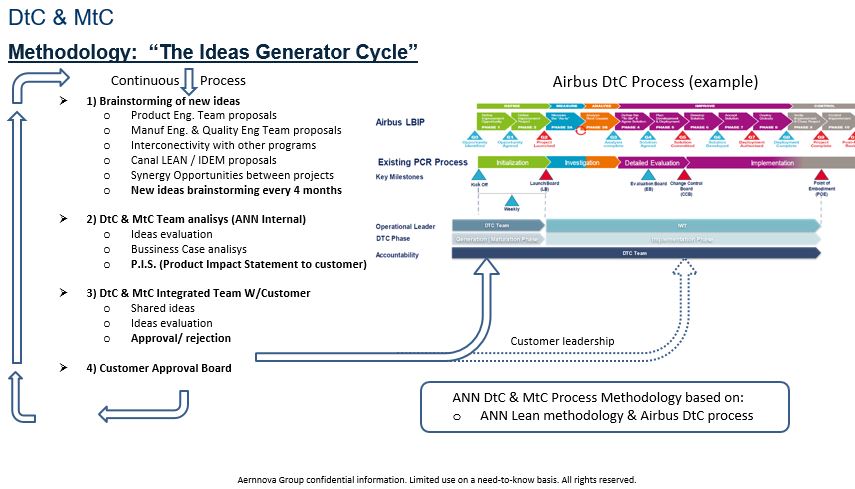

1º) The first thing will be to clearly define the Objective.

2º) To establish the Methodology.

3º) To Build the Work Tools.

4º) To Identify Key People.

5º) To collaborate with Teams

Consequently, opportunities for Synergies between programs and teams will appear, we will facilitate the compilation and application of Know-how between nuclei that allow us to identify solutions already given in some programs and that are feasible in others.

But is this enough? Don´t think so, I think something more is being requested to us.

Let’s see some examples:

-Identification of parts during intermediate manufacturing processes.

-Optimization of the use of raw Mat in machining.

-Selection of new materials for use in automated laminating processes.

-Removal of foreign objects in composite laminates.

-Optimization of Stretching Processes in sheet metal parts.

For all of them we ask ourselves the following questions:

-What is the current State of the Art?

-Are we applying solutions and technologies of the S-XXI, or are we still anchored perhaps in the S-XIX?

-Are we aware that perhaps in the mobile we carry in our pocket there is much more technology and applications developed than everything implemented in our plants? Our mobile is capable of recognizing our face, our footprint, the music we listen to. Why are we not able to identify the piece in front of us just by “seeing” it with an optical system coupled to a “smart” software?

-Even more: would we be able to carry out a metrological inspection of a piece “just by seeing it” by means of a calibrated optical system, and thereby immediately obtain its dimensional report?

Conclusions

There are many opportunities offered by the day-to-day activities of our projects in production. Opportunities to contribute our past knowledge and in turn to increase our future knowledge. Knowing how to capture and expand this knowledge is key to optimizing future projects (offers) and present projects (continuous improvement).

Our clients ask us to carry out a Continuous Improvement of our projects and that in turn we support them in their proposals.

The challenges that this entails affect and involve all the agents of the ANN Organization (Engineering, Supply, Production Engineering, Logistics,…).

Our objective is not only to meet the client’s requirements, but also to provide a Differentiating Element with respect to our competitors, which helps to give Added Value to our Clients.

In this way we can be in a Preferential Position to participate in the development and manufacture of new projects.