Citius, altius, fortius. Faster, higher, stronger. This motto was first used at the 1900 Paris Olympics. In Aernnova’s production, we could propose something similar: greater cadence, cheaper, total quality (although in Latin it doesn’t sound as good as the Olympics one). Continuous improvement and the market are leading us to increase production to meet future demand (the goal seems to be 100 airplanes per month of a single model), reduce costs to be competitive, and, of course, offer an immaculate product, without forgetting the improvement in the ergonomics of the workplaces.

Well, at the Berantevilla facilities, they’ve taken this seriously and, through a series of R&D projects, are advancing the plant’s technical development toward an industrial assembly model that includes perception systems (augmented reality), adaptive tooling, continuous process (CP) and product (CPM) measurement, best fit connection…

In the Masterly project, AERNNOVA team and with the collaboration of Tekniker, develops a concept of a use case focused on a high-speed production line, with the aim of reducing the lead time and quality issues in the handling and placement of large panels, common in aeronautical structures.

Aernnova team for the Masterly project: Luis, Manolo, Goretti, and Javier

On the one hand, smart overhead cranes are being deployed to handle large aeronautical parts with precision and safety. Features such as inertial anti-roll control, collision avoidance and 3D perception ensure precise and safe operations, while human-machine interaction provides flexibility, improving efficiency, safety and competitiveness in aeronautical manufacturing.

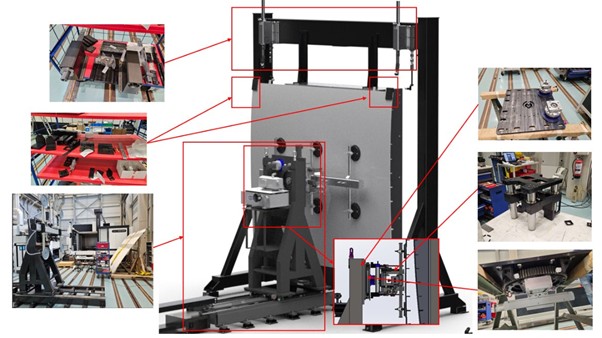

On the other hand, a system has been developed that places the panel in the Jig with the following functionalities:

-Automated mechatronics for part gripping, handling, and high-accuracy positioning (4 axis) which can be mounted on a frame moved by an AGV (Automated Guided Vehicle)

-Seamless human-operator interaction via augmented reality (AR)

-Automated part grasping point calculation and AR visualization for correct balance of the center of gravity of the set

-High-precision automated final positioning with artificial vision (AV)

-Monitoring of forces in the attaching anchor points with sensorized pins of 10mm diameter

These technologies reduce worker stress and fatigue while improving task completion times and quality in the execution of tasks.

The smart crane is already operational, and by the end of November, we will have the handling system at the Berantevilla facility to perform final tests and validate the entire system.

Frequentia maior, vilius, qualitas summa. As I said, it doesn’t sound so good…

(This project has received funding from the European Union’s Horizon Europe programme under Grant Agreement N. 101091800)