In April 2020, Airbus selected Aernnova and entrusted it with the design and development of the ACT (Auxiliary Central Fuel Tank) project in an effort to increase the range of the Airbus A-220 in its 100 and 300 models.

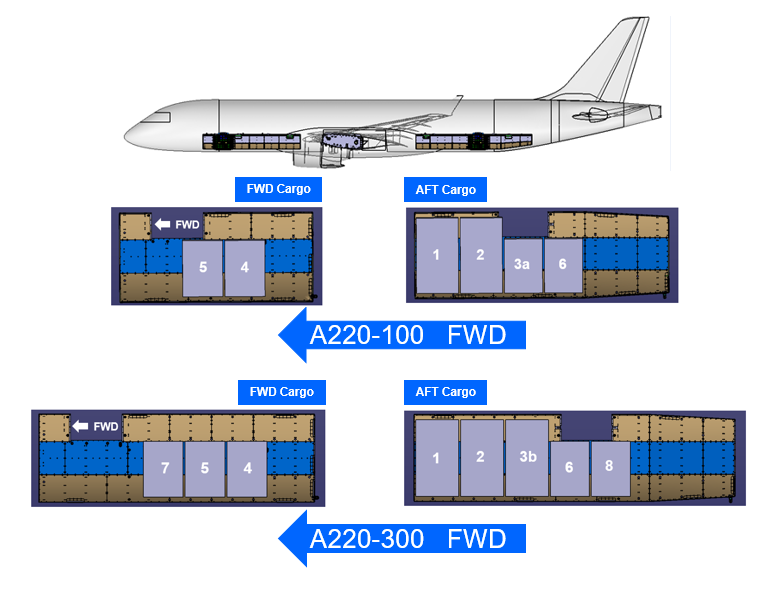

The ACT project was aimed at extending the aircraft’s fuel tanks to provide an increase in the total range of the aircraft. To achieve this objective, the project required the development of an industrial process for the installation of the auxiliary tank, placing it in the cargo compartments and connecting it to the central box (CWB), which is also a fuel tank.

The scope of the project involved product design, the design of the necessary tooling, the development of new production processes, the definition of specific work orders, the conception of special work patterns and the execution of all of the above on an aircraft with a completed first flight.

An additional aspect that added to the complexity of the challenge was the need to execute the work at the Airbus facility in Mirabel, Canada, in coordination with and under the supervision of the customer.

Aernnova Aerostructures Álava coordinated this work and the participants from the different companies in the group. The fact that the final phase of the project had to be carried out at the customer’s facilities, despite being a major challenge, was perfectly in line with the experience of the personnel of Aernnova Aerostructures Alava, which has significant and valuable experience in providing services at the customer’s facilities or at those of other companies of the Group (Aernnova Mexico or Harbin Hafei Airbus in China) for the transfer of the assembly of the A350 rudder and elevator, support for the start-up of the assembly of the A350 doors at Aernnova Composites Illescas, support for the Tanker project at Airbus Military in Getafe or, most recently, support for Aernnova Évora with the ramp-up of the Embraer Praetor wing).

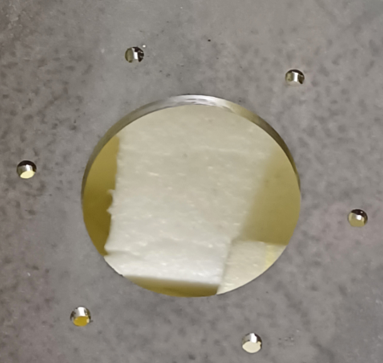

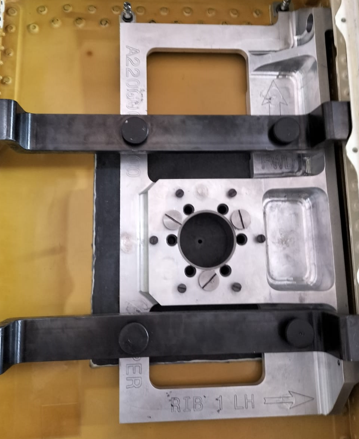

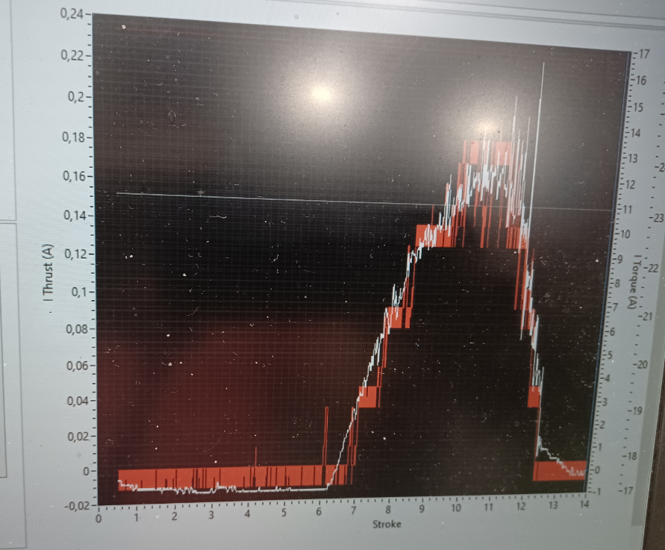

The coordination of all those involved was essential to ensure the smooth running of this highly complex process; a complexity that was not derived exclusively from the technical development required, but also from all the special conditions that the execution would entail: large drilling diameters of up to 63mm, strict execution deadlines, complex and limited access to the aircraft’s work area due to being executed in a Central Wing Box (CWB) already installed in a completed aircraft and with a first flight executed. Given all its characteristics, the challenge could be described as a major one.

The technical development of the drilling process and the installation of associated systems, totally innovative processes with respect to what had existed up to that time, involved many hours of analysis and preparation prior to the execution, above all in the search for alternatives to achieve satisfactory drilling due to the important limitations involved in the fact that they had to be carried out in a finished aircraft and with the requirement of an ATEX environment (explosive atmosphere) and that the drilling had to be carried out in critical areas of the structure of the Central Wing Box of the A220 (Rear Spar, Front Spar and Upper Skin).

Now, after almost 3 years since the start of the project, the drilling activities on the first aircraft have been completed with an excellent result that has left the customer fully satisfied, confirming the viability of this project and further strengthening the customer’s confidence in the Aernnova Group in the face of major challenges that, both technically and in terms of time, other competitors cannot overcome.

The next phase of the project will be the first flight of an A220 with integrated ACT system, once Airbus completes the integration work, estimated for July 2023.

ACT’s design will provide operators with the flexibility to add additional tanks to an in-service aircraft on an as-needed basis in a simple process, thanks to the structural and systems infrastructure generated by Aernnova.

In fact, it can be clearly stated that the design of the auxiliary fuel system combines robustness, reliability, flexibility and cost in a balanced way.

A220-100: Addition of 1 to 6 tanks for at least 11,000 lb of additional fuel, 8000 lb with 4 tanks aft (2 x 2500 lb + 2 x 1500 lb) + 3000 lb with 2 tanks forward (2 x 1500 lb).

A220-300: Addition of 1 to 8 tanks for at least 15,000 lb of additional fuel. 10,500 lb with 5 tanks aft (3 x 2,500 lb + 2 x 1,500 lb) + 4,500 lb with 3 tanks forward (3 x 1,500).

With this project Aernnova overcomes a demanding technical and industrial challenge in a growing segment of the support market.

Technological Development and Innovation is one of Aernnova’s strategic growth vectors to meet this ambitious objective motivated by the needs of our customers and adding value to the products and services for our customers.

And all this would not have been achieved without the dedication, effort and constant will of all the participating nuclei (Aernnova Aeroestructuras Álava, Grupo Industrialización, Aernnova Engineering Division, Aernnova Aicraft Services, Aernnova Composites Illescas, Aernnova Andalucía, Fibertecnic and Aernnova Aerospace), who have demonstrated a very high level of professionalism, technical rigour, expertise and commitment, for which we can only thank them and congratulate them on the success achieved.