Componentes Aeronáuticos Coasa is located in the Technological Park of Galicia (Tecnópole) in San Cibrao Das Viñas, Ourense.

It was founded in 2001 as a subsidiary of the Aernnova group, thus becoming a leading aeronautical company in the manufacture of composite components for the aeronautical sector, with a recognizable traction in the Galician economy and great international projection.

With more than 20 years of experience, Coasa designs and manufactures composite structures and components for the main OEMs.

Aircraft of the giants of the sector such as Airbus or the Brazilian Embraer have parts made in Orense.

We have an area of 27.000m2 of Hand Lay Up technology, where we highlight as main facilities 1.400 m2 of clean room with 46 projectors, 3 autoclaves of 14, 10 and 3.8 meters, 2 automatic ultrasonic inspection machines.

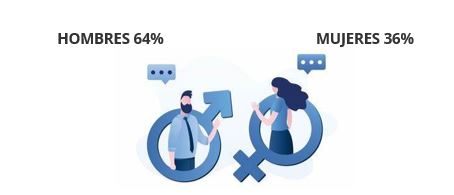

But what we are most proud of is our large team of 352 professionals, where 54% of the staff has more than 15 years of experience, with an average age of 44 years.

Our greatest challenges are always focused on the future

Coasa manufactures more than 1,000 serial deliverable NPs and several hundred more as spare parts. In a typical month, more than 3,000 sales order lines are handled.

Among the different projects we are currently working on, we have a common challenge: Increased rates, which is very good news!

We highlight two packages of the Airbus A320 model:

TTP’s (Main Landing Gear Traps), with rate manufacturing shared with Fibertecnic.

Seal Plates of the single source Wing with delivery in England.

In the A320 rate increase, going from 40 aircraft in 2021 to 57 in 2023 and reaching a rate of 75 in 2026, will place us in a situation of 87% growth in 5 years.

Coasa also participates in several packages of the A350 Program (HTP parts with delivery in Puerto Real, Air Inlet engine with delivery in Nantes, Wing WingTESS with deliveries in Bremen and Toulouse, Elevator and Rudder with deliveries in Harbin) will return in 2025 to pre-covid levels, going from less than 5 A/C month in 2021 to 10 AV/month in 2026.

Significant rises are also expected at Embraer. The Praetor program, in which Coasa manufactures the VTP and HTP spars, will reach rate 9 in 2025 (rate 6 currently). Significant increases are also expected in the KC-390 program in which our company also participates.

New Program and new Customer: PREMIUM AEROTEC (AIRBUS)

This work package consists of three families of parts that are part of the A350 fuselage: Buttstraps, Door Surrandings and Sewing Angles.

The Buttstaps package is manufactured at ACI, the group’s company located in Illescas. We received the tooling last May and have already started the FAI molding process and the first prototypes. The Door Surroundings and Sewing Angles packages are manufactured at Coasa,

Both Coasa and ACI will be performing throughout 2023 and 2024 the qualification, FAI and ramp up processes.

Zero Latency -INFOR

Like most of the companies in the group, we are immersed in the ERP change, an intense and huge work that conceptually consists of adapting the current way of working to the new system capabilities and then migrate all the information to the new more efficient system.

Ramón Serén, Coasa’s Focal Point for the project, in addition to being in the manufacturing engineering, desgin to release and unique code working groups. He sees this opportunity and this project as a huge challenge:

“Taking advantage of the benefits of the new system and the knowledge acquired by all colleagues, standardize the definition of manufacturing flows within the company and with the rest of the core companies, so that we all define our processes in the system in the same way.”