“Honda Aircraft Company Announces Plan to Commercialize New Light Jet”

This is how the HondaJet company announced last June 13, 2023, on its website, the commercial launch of its new light jet HA-480, also known as HondaJet 2600 and now with the new commercial name of HondaJet Echelon, the first jet capable of non-stop transcontinental flights across the United States.

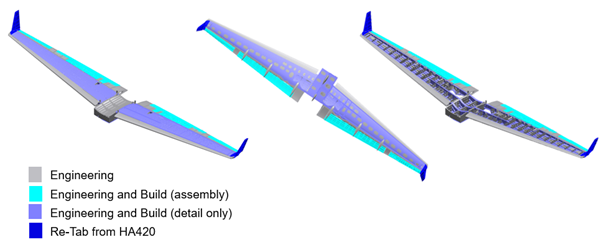

This was a recent publication about a program with a long way to go for Aernnova and in particular for Aernnova Engineering, which has been collaborating on this program with Honda since the beginning of 2019, when we were invited to the JDP phase (Joint Definition Phase), a phase that was carried out at the Aernnova Miñano (Álava) facilities for only 3 months. As a result of that work, in June 2019, the agreement for the wing design (excluding systems, leading edge and winglet) was signed and the Kick Off was held, giving the green light to a path that we are still following today.

It was a DtB project, i.e. engineering support. It was an important package, not only because of the number of hours achieved, but also because it was a new client. It was also a demanding project because of the planning involved, which required to celebrate CDR in a year and a half passing through PDR. In addition, the most demanding criterion for the CDR was the release of 80% of the package design, i.e., we had to have practically the entire package released before starting industrialization.

While the wing design was being started, the commercial departments were doing their work and as a result, the second agreement arrived in November 2019: design and manufacture of the FAS mobile surfaces (Flap, Aileron, Spoilers), even more interesting than the wing design, because it increased our participation, and strengthened our ties with this new customer as a supplier of engineering services, while paving the way from the point of view of component production. The fact that Aernnova is a first level supplier of integral services led to the manufacturing of the main structural parts of the aircraft wing, skins and spars, taking advantage of the concurrence between the Tarazona plant and Aernnova Engineering, both for the HA-420 and the HA-480. The manufacture and assembly (BtP) of the empennages and their moving surfaces (Rudder and Elevator) was also achieved. Last but not least, Aernnova Engineering obtained the design of the wing assembly tooling.

In December 2020 the PDR for the FAS package was passed and in March 2021 the PDR for the wing was passed.

In March 2022 the CDR for the FAS package also passed, and in March 2023 the wing one. Both packages involved up to 65 engineering resources distributed between the Derio, Madrid and Vitoria offices in Spain. This development phase, which was only supposed to last 9 months and finally lasted 2 years, included, in addition to the required releases, an extra loop of structural loads, and a weight reduction campaign on the structure, increasing the number of working hours for Aernnova Engineering.

A PROJECT WITH SOME BUMPS IN THE ROAD

The HondaJet HA-480 was undoubtedly a tough challenge for Aernnova, given that the aerodynamic tolerance requirements were very high on products with very low thicknesses. As can be deduced, combining the three requirements (low price was the third one) was a major handicap that would force a brutal level of control and management, to squeeze the capabilities of all areas, and to look for solutions out of the ordinary. In addition, only “Aernnova” suppliers or suppliers from the American continent were allowed.

Honda has selected Aernnova as its wing design supplier because of its experience and knowledge in the aeronautical sector for more than 25 years. This was demonstrated during the pre-conceptual phase. They were undoubtedly looking to improve their products with our solutions and problem solving. We also had some advantages, we used the same PLM (Team Center) but adapted to their needs, references and utilities.

I think it is worth mentioning that Aernnova Engineering has also learned some things from Honda, especially during the release phase of the drawings in the GD&T area. Also the quality standards in Catia models, and PLMs were much higher than other projects, and they forced us to reinforce the quality assurance measures beyond the normal. Macros have even been developed internally to automate the checking. It has forced us to recognize shortcomings, to develop, to improve and to innovate. And we have also learned about tools and utilities such as 3D pdf that allow us to visualize 3D geometry together with its FT&A through an Acrobat viewer.

RELATIONSHIPS AND FEELINGS

Honda Aircraft Company is a wholly owned subsidiary of Honda Motor Company. It is headquartered at Piedmont Triad International Airport in Greensboro, North Carolina. It is a young, inexperienced company that wanted Aernnova to learn and mature in the aviation industry, with only one aircraft on the market. Today, the HondaJet Elite is considered a benchmark in its segment in the global business jet market. It is the fastest light jet in the world, the one that flies at the highest altitude, the quietest and the one that consumes the least fuel, and also a sales leader with more than 200 aircraft built and sold.

If there is one thing to highlight about Honda’s staff, it is their cordiality, empathy and attentiveness. Despite being the customer, their dealings with Aernnova, at all levels, have always been friendly, with an excellent mutual understanding of each other’s needs. Proof of the mutual trust generated throughout this time is the announcement of the commercialization of the aircraft that was launched at the recent HA-480 supplier conference. Aernnova was designated as Benchmarking Supplier. We would certainly look forward to collaborating with Honda for many years to come.

.